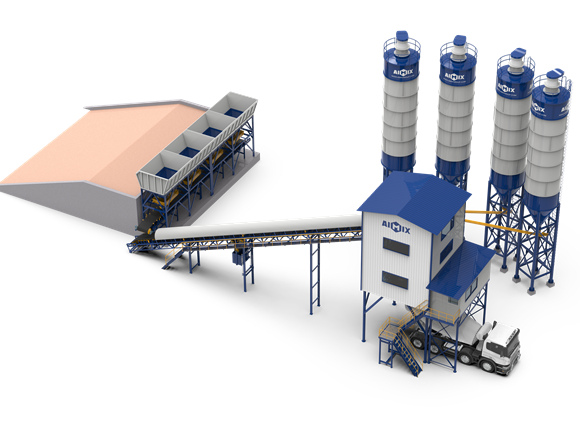

Concrete batching plant has various operation and production information in our company. There are various types like ready mix concrete plant, small concrete plant, large concrete plant, belt type concrete plant, etc. If you have needs about concrete batching plant, please get in touch with us as soon as possible.

| Model | AJ-35 |

| Theoretical Productivity (m³/h) | 35 |

| Mixer Model (Mixer Output L) | JS750 |

| Mixer Power (kW) | 30 |

| Mixing Cycle Period (s) | 72 |

| Rated Input Volume (Model of Batching Machine L) | 1200 |

| Max.Aggregate Size (mm) | Φ60 |

| Max. Discharging Height (m) | 4.1 |

| Overall Weight (ton) | ≈18 |

| Installation Power (kW) | ≈75 |

| Model | AJ-35 |

| Theoretical Productivity (m³/h) | 35 |

| Mixer Model (Mixer Output L) | JS750 |

| Mixer Power (kW) | 30 |

| Mixing Cycle Period (s) | 72 |

| Rated Input Volume (Model of Batching Machine L) | 1200 |

| Max.Aggregate Size (mm) | Φ60 |

| Max. Discharging Height (m) | 4.1 |

| Overall Weight (ton) | ≈18 |

| Installation Power (kW) | ≈75 |

Concrete Plant Specifications: Please click below and learn more.

| Model | Bucket type | Belt type | ||||||

| AJ-25 | AJ-35 | AJ-50 | AJ-75 | AJ-60 | AJ-90 | AJ-120 | AJ-180 | |

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 75 | 90 | 120 | 180 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS1000 | JS1500 | MAO3000/2000 (SICOMA) | MAO4500/3000 (SICOMA) |

| Mixer Power (kW) | 18.5 | 30 | 2×18.5 | 2×30 | 2×18.5 | 2×30 | 2×37 | 2×55 |

| Mixing Cycle Period (s) | 67 | 72 | 72 | 72 | 60 | 60 | 65 | 65 |

| Rated Input Volume (Model of Batching Machine L) | 800 | 1200 | 1600 | 2400 | 1600 | 2400 | 3000 | 4500 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ80 | Φ60 | Φ80 | Φ80 | Φ80 |

| Standard Aggregate Bin Capacity (m³) | 3×3 | 3×5 | 3×8 | 3×12 | 4×7 | 4×15 | 4×15 | 4×20 |

| Category of Aggregate | 2/3 | 2/3/4 | 3/4 | 3/4 | 4/5 | 4/5 | 4/5/6 | 4/5/6 |

| Powder Storage Silo (ton) (Optional) | 1×50 | 2×50 | 1×100 | 2×100 | 2×100 | 3×100 | 4×200 | 4×200 |

| Max. Discharging Height (m) | 3.8 | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 | 4.3 | 4.3 |

| Weighing Range & Accuracy of Aggregate (kg) | (300~1000) ±2% | (300~1000) ±2% | (300~1000) ±2% | (300~1500) ±2% | (300~1000) ±2% | (300~1500) ±2% | (300~2000) ±2% | (300~3000) ±2% |

| Weighing Range & Accuracy of Cement (kg) | (100~300) ±1% | (100~300) ±1% | (100~750) ±1% | (100~900) ±1% | (100~750) ±1% | (100~900) ±1% | (100~1200) ±1% | (100~1800) ±1% |

| Weighing Range & Accuracy of Water (kg) | (60~150) ±1% | (60~150) ±1% | (100~300) ±1% | (100~400) ±1% | (100~300) ±1% | (100~400) ±1% | (100~600) ±1% | (100~800) ±1% |

| Weighing Range & Accuracy of Additive (kg) | (5~20) ±1% | (5~20) ±1% | (5~20) ±1% | (5~25) ±1% | (5~20) ±1% | (5~25) ±1% | (5~30) ±1% | (5~50) ±1% |

| Overall Weight (ton) | ≈15 | ≈18 | ≈23 | ≈30 | ≈40 | ≈68 | ≈93 | ≈101 |

| Installation Power (kW) | ≈65 | ≈75 | ≈100 | ≈140 | ≈110 | ≈160 | ≈220 | ≈290 |

| Power Supply |

380V/220V/415/440V, 50/60HZ, 3Phase |

|||||||

| Model | Belt Type | ||

| AJY-25 | AJY-35 | AJY-50 | |

| Theoretical Productivity (m³/h) | 25 | 35 | 50 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 |

| Mixer Power (kW) | 18.5 | 30 | 2×18.5 |

| Mixing Cycle Period (s) | 67 | 72 | 72 |

| Rated Input Volume (Model of Batching Machine L) | 800 | 1200 | 1600 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 |

| Standard Aggregate Bin Capacity (m³) | 2×3 | 2×5 | 3×5 |

| Category of Aggregate | 2/3/4 | ||

| Powder Storage Silo (ton) (Optional) | 1×50 | 2×50 | 1×100 |

| Max. Discharging Height (m) | 3.8 | 3.8 | 4.1 |

| Weighing Range & Accuracy of Aggregate (kg) | (300~1500)±2% | (300~1500)±2% | (300~3000)±2% |

| Weighing Range & Accuracy of Cement (kg) | (100~300)±1% | (100~300)±1% | (250~900)±1% |

| Weighing Range & Accuracy of Water (kg) | (60~150) ±1% | (60~150) ±1% | 80~300)±1% |

| Weighing Range & Accuracy of Additive (kg) | / | (8~20) ±1% | (8~20) ±1% |

| Overall Weight (ton) | ≈15 | ≈22 | ≈26 |

| Installation Power (kW) | ≈61 | ≈73 | ≈92 |

| Power Supply | 380V/220V/415/440V, 50/60HZ, 3Phase | ||

Concrete Plant Information

1. We can offer the relevant certification qualification, which is not only a business card, but also has the first step to enhance mutual trust. The customer comes with sincerity. This is a certified qualified enterprise cooperation.

2. If you can visit the factory, you can find that the team size of large manufacturers. The talent reserves are very good. Workshop has a high level is very easy to see. You can imagine a set of equipment from a high-tech production line, high-quality professionals and enterprises solemnly promise. Then the quality can be assured use.

3. We have different cases. Through the case can examine the overall strength of the company, but also to see if there are similar to their own needs. The uses can learn from the relevant experience.

4. If the manufacturer can provide service guarantee to the customer from the pre-sale, in-sale, after-sale. Then it must be out of extreme responsibility for its own team and products. It is precisely because the product has a high-quality basis. The manufacturers can have such confidence for their own products responsible.

Concrete Batching Plant Production Management System

1. No production instructions issued by the station master of the concrete mixing station or the project management department shall be turned on.

2. No production or maintenance shall be discontinued without the permission of the project department.

3. Accurate input mix ratio; Carefully re-inputting all the data, after the test personnel, the operator after the confirmation of the correct signature record before production.

4. Production is strictly in accordance with the mix ratio. No one is allowed to increase or decrease raw materials, admixtures and water consumption at will without written instructions from laboratory personnel. Mixing time depends on the state of concrete, without the consent of the test personnel may not arbitrarily increase or decrease.

5. In production, we should closely observe whether the measurement is accurate or not, and adjust the difference in time in excess of the prescribed error. All measurements at no load shall be in the minimum range. Other anomalies in the metering system must be reported and handled in a timely manner.

6. The error of cement, admixture and water, when it is found that the quality of cement and admixture is not enough, it should find out whether the dragon is blocked or not in time, and eliminate it in time, the error of aggregate, and the reason and manual compensation and record should be found when the error exceeds the standard.

Concrete Batching Plant Operation Information

It is responsible for the safe, swift and accurate delivery of concrete to the pouring site. Before the mixing truck is shipped with concrete, it is responsible for the careful inspection of the mixing truck the inner wall of the truck must be cleaned. There must be no water in it. The car hopper must be cleaned after the daily shipment of concrete work or when the discharge time exceeds 30 min. After the concrete is transported to the pouring site, it is responsible for paying attention. There is collecting the slump and ease of the concrete mixture. It can have the giving timely feedback to the production attendant and the tester.

Why To Learn Concrete Batching Plant Safety

When the performance of the concrete mixture has reached the specifications, design and construction requirements. The concrete construction mix ratio shall be strictly followed; if the concrete mixing properties cannot meet the specifications, design and construction requirements. The concrete construction mix ratio shall be analyzed and adjusted immediately by the test personnel, until the performance of the concrete mixture meets the above requirements. The adjusted concrete construction mix ratio shall be strictly followed. The test personnel shall reissue the concrete construction batching list according to the adjusted concrete.

Concrete Batching Plant for Sale

Concrete batching plant is the important mixing equipment. There are various types and equipment. You can choose the right types and tons. We have professional factory to offer the customized concrete batching plant. If you have needs, please get in touch with us as soon as possible.