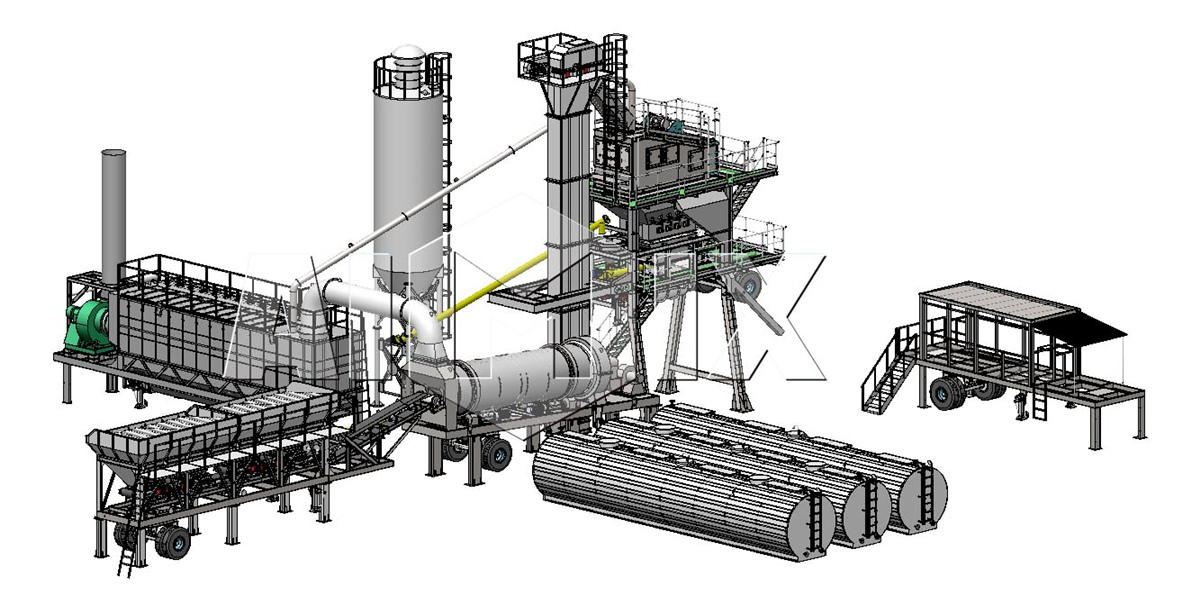

Asphalt plant consists of many systems. It also known as asphalt concrete mixing plant, asphalt concrete mixing plant. It refers to a complete set of equipment for mass production of asphalt concrete. According to the mixing method, it can be divided into forced intermittent type and continuous production type; According to the transportation method, it can be divided into fixed type, semi-fixed type and mobile type. It is the necessary equipment which is widely used for highways, grade roads, municipal roads, airports, and ports.

News for you

ALYJ10 simple batch asphalt plant to Malaysia

ALYJ60 simple batch asphalt plant to Philippines

ALT series drum asphalt plants to different countries

ALQ series asphalt plants

Various Types Of Asphalt Plant

The asphalt concrete mixing equipment has the various functions. It mixes the aggregates and fillers of different particle sizes in a prescribed ratio, and uses asphalt as a binder to mix them into a uniform mixture at a prescribed temperature.

Asphalt concrete mixing equipment is one of the key equipment for asphalt pavement construction, and its performance directly affects the quality of the paved asphalt pavement. The mixing plants required for different construction requirements are different. The basic classifications currently available on the market are as follows:

Production Capacity

According to the production capacity, it can be divided into small model, medium model, and large type.

Handling Method

According to the handling method, it can be divided into mobile type, semi-fixed types and fixed type.

The mobile type. It has good design system. The silos and mixing pots has the their own tires, which can be transferred with the construction site. It suitable for country roads and low-grade highway projects.

The semi-fixed type. It is used for road construction. The equipment is installed on several trailers, assembled at the construction site.

The fixed type. It can be fixed working place of the equipment. It is used in the engineering concentration and urban road construction.

Stirring Method

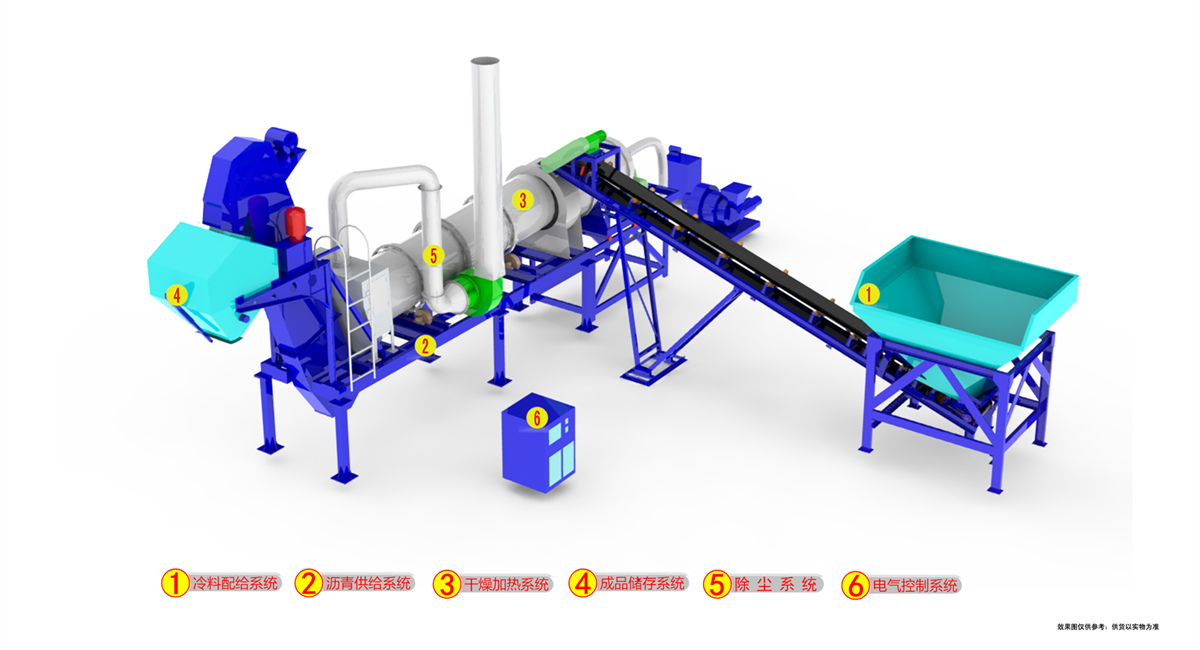

According to the process flow method, it can be divided into continuous drum type and intermittent forced type.

The continuous drum type. According to the mixing method, the drum mix type asphalt plant is produced by continuous uninterrupted stirring. The heating and drying of the aggregate and the stirring of the mixture are continuously performed in the same drum.

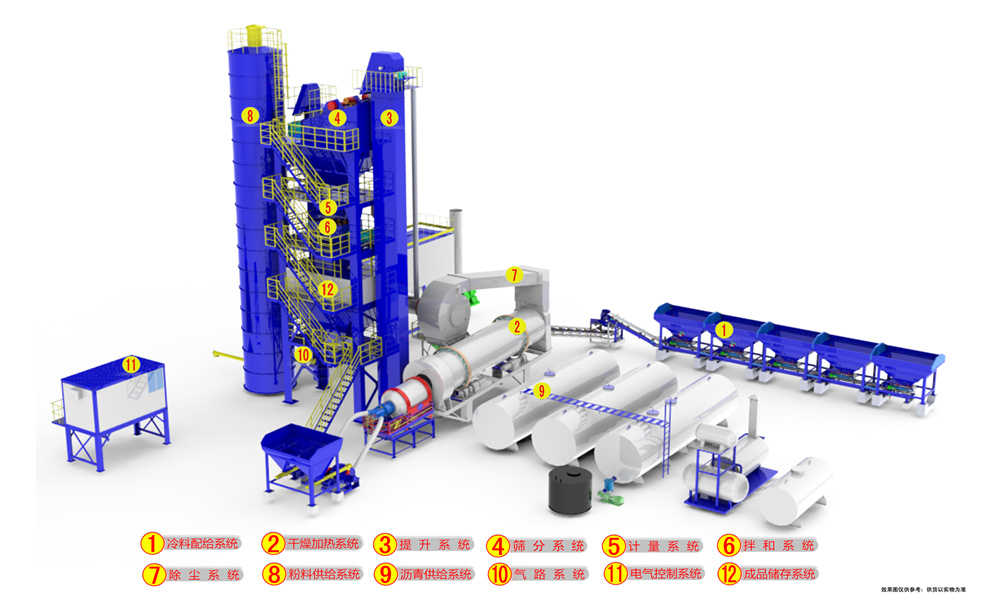

The forced batching type. It is the heating and drying of the aggregate and the stirring of the mixture are forced to be periodically performed. The equipment is stirred separately in one pot and one pot. Each pot is stirred for 45 seconds to 60 seconds. The yield depends on the model of the equipment.

The forced mixing plant operation

Various Advantages of Asphalt Plant System

Maintain the advancement of Technology with international standards

Our products are designed and produced according to European advanced technology and standards. Our team has the responsibility for researching the domestic advanced technology trends and the latest technology, which ensure the technology and the quality of our products are synchronized with the international advanced level.

Product quality is recognized by authorities

Our firm’s equipment has obtained standard certifications in China. Of course, it also obtains the international standard design. These products has been recognized by our own customers.

Complete product line, product serialization

Our firm has a complete product line to provide customers with various specifications of asphalt mixing equipment. The equipment can adopt the diesel, electric, hydraulic type to offer power. The complete product line provides customers with a variety of options to meet various engineering needs.

Advanced electronic weighing system

It adopts the three point pull sensor. The aggregate measurement adopts a two cylinder three stroke structure. The asphalt measurement adopts a dynamic secondary measurement method. The power material adopts a frequency conversion spiral structure. The advanced metering method ensures the accuracy and stability of the metering system of asphalt mixing equipment.

Energy saving and environmental protection

The customers can choose variable frequency control technology, which can ensure the stability of equipment and reduce energy consumption. Our team can adopt various measures, which can reduce noise and dust during equipment operation and reduce waste discharge.

Adopting the computer control system and remote control system

It has industrial Ethernet control system, which has control functions and modular equipment. The system is more compact and stable. We can meet the requirements of quick installation on site. In addition, it can be easy to move. The excellent service team can provide the customers with advanced preventive service, which can ensure the normal operation of the equipment.

The first class matching parts

High quality parts are the basis for the reliability, stability, and durability of asphalt mixing equipment. We adopt the matching parts of European first class brands, which fundamentally guarantees the low energy consumption, low failure rate, low maintenance cost and long life of Aimix products.

Customized recycling solutions for customers

We introduce the world’s advanced recycling asphalt mixture recycling technology and recycling equipment. It can provide a variety of asphalt mixture thermal regeneration schemes and equipment according to the customers’ needs. The proportion of recycled materials is promoted.

Asphalt Plant Working Principle

Asphalt mixing equipment is a mechanical device for producing various asphalt mixtures. It is suitable for engineering departments such as roads, airports, terminals, parking lots, and freight yards. It has many functions with mixing aggregates and fillers of different particle sizes in a prescribed ratio. In addition, it uses asphalt as a binder to mix them into a uniform mixture at a prescribed temperature.

Commonly, there is used asphalt mixture materials including asphalt concrete, asphalt gravel, tar sand, etc. With the extensive application of modern new technologies and new materials, it uses emulsified asphalt, epoxy asphalt, modified asphalt, decolorized asphalt with cold mix, warm mix, and hot mix of various asphalt concrete. This equipment is one of the key equipment for asphalt pavement construction. Its performance directly affects the quality of paved asphalt pavement.

Wide Applications of Asphalt Plant

According to the customer’s working condition, the asphalt mixing equipment developed by Aimix Group has a wide range of applications. We design many different types including forced intermittent asphalt mixing equipment, mobile continuous asphalt mixing equipment, double drum asphalt plant, etc. Among them, the asphalt warm mix technology adopts many international famous applications, which is suitable for paving asphalt roads of all grades and paving of various levels. It has important promotion value for areas with high air quality requirements.

Professional Asphalt Plant for Sale

Asphalt plant has many different types in our company. You can choose suitable type for your business. As the reliable manufacturer and supplier of asphalt equipment, we can meet many customers’ demands for asphalt needs. We are the famous brand and our products have exported over 60 countries and regions from all over the world. If you want to learn more useful information, please get in touch with us as soon as possible.