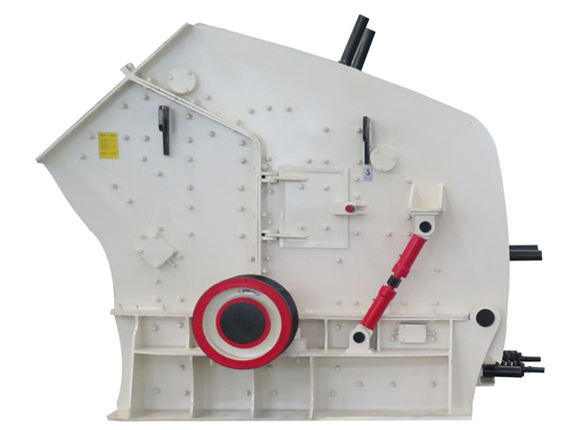

Impact crusher has the special structure and has no key connection and with strong rigidity. In addition, it has impact resistant and wear resistant. It is widely used in building materials, ore crushing, railways, highways, energy, transportation, energy, cement, mining, chemical and other industries for medium and fine materials. The size of the discharge material can be adjusted, and the crushing specifications are diversified.

| Model | APPF-1210 |

| Rotor size (mm) | Φ1260×1050 |

| Feed opening (mm) | 465×1155 |

| Max.Feed size(mm) | 250 |

| Capacity(t/h) | 70-130 |

| Power | 110(150) |

| Dimension(L*W*H)(mm) | 2585*2052*2810 |

| Weight (t) | 16 |

Various Types of Impact Crusher

There are divided into three types in our company including the PF impact crusher, PFT reinforced impact crusher, and PFS impact crusher according to different use functions. In addition, there are various crusher machine models and sizes in our company. You can find out the popular types including APPF-1007, APPF-1010, APPF-1210, APPF-1212, APPF-1214, APPF-1315, APPF-1320, APPFV-1007, APPFV-1010, APPFV-1210, APPFV-1214, APPFV-1315, APPFV-1320 and others.

APPF impact crusher

The impact crusher can process various coarse, medium and fine materials with a crushing feed size of not more than 500mm and a compressive pressure of not more than 350Mpa. When it increases the number of material hits, hard extrusion, friction reduction, it can reduce loss and extend the service life of wear parts.

It is widely used in industrial sectors such as metallurgy, mining, cement, chemical, refractory materials and ceramics, as well as highway construction, water conservancy projects, construction gravel, and mechanism sand processing.

APPFT reinforced impact crusher

The type adopts the advanced technology to design and manufacture various models. It uses high quality material to produce the crusher with heavy duty rotor design, which is the important part in impact crushing machine. It plays the important role in the crushing operation, so our company researches and develops the heavy duty rotor and get more rotational internal.

APPFS impact crusher

The type’s max feed size can achieve to 1000mm. Compared with traditional crushing machine, its ratio has been greatly improved. It can freely switch between primary crushing and secondary crushing, which improves the high efficiency of crushing.

Vertical Shaft Impact Crusher

The machine is widely used in various crushing and fine crushing of various hard and brittle materials such as rock, abrasive, refractory material, cement clinker, quartz stone, iron ore, concrete aggregate. It is suitable for construction sand and gravel for road construction. It plays the important role for production of high quality machine sand.

Excellent Advantages of Vertical Shaft Impact Crusher

- It has the function of fine crushing and rough grinding.

- The product has excellent grain shape. It is cubic and has a very low needle-like content. It is suitable for aggregate shaping, artificial sand making and high-grade highway aggregate production.

- During the production process, the stone material can form a protective bottom layer, and the body is wear-free and durable.

- The product has a high bulk density and minimal iron contamination.

- The ability to pass non-crushed materials is strong, and the moisture content of the material is small.

Impact Crusher And Jaw Crusher

The impact crusher is named according to the working principle. It makes full use of the principle to crush various materials. It is the crusher equipment which is more fine than the jaw crusher. It is mainly used for fine crushing operations in the stone production line. Generally speaking, it has the good cooperation with the jaw crusher in the operation.

The Difference Between Jaw Crusher and Impact Crusher

Jaw crushers and impact crushers are suitable for crushing materials of various hardness. The jaw crusher is mainly used for coarse crushing, while the impact crushing machine is used for medium crushing and fine crushing. Owing to the material size after extrusion treatment by the jaw crusher, it is not ideal, and the needle content is large. Then, the impact crush machine is usually configured for further shaping, so the two are relatively common in the crushing production line.

Jaw crusher working principle

The jaw crusher is the equipment by crushing. It consists of two jaws, which are composed of mobile jaw and static jaw with completing the material crushing. When operation, the motor drives the eccentric shaft to rotate through the pulley, so that the moving jaws are periodically close to and away from the stationary jaw. The material is subjected to multiple forces such as pressing, smashing and rolling, and the crushed material gradually falls until it is discharged from the discharge port.

Impact crushing machine working principle

It adopts the plate hammer on the high speed moving rotor. The material has high speed impact. The broken materials are crushed at the end of the crushing chamber. Then, it rebounds from the counterattack to the hammer. During this process, the materials will collide with each other, which causes cracks and looseness. When the material particle size is smaller than the gap between the counterattack plate and the hammer, it is discharged outside the machine.

Various Advantages of Impact Crusher

Excellent Performance

It has large crushing ratio and low energy consumption, so it has high crushing efficiency and low power consumption.

Uniform particle size and less over-grinding

In the crushing process, the useful minerals are first broken along the joint plane to facilitate the separation, especially for useful minerals of coarse-grained inlays. The product has a uniform particle size and less pulverization.

Good processing ability and product shape

It can be used control for the all kinds of coarse, medium and fine materials with high efficiency, economy and adaptability. By adjusting the gap between the counterattack plate hammer, the particle size of the discharge can be effectively controlled. The shape of the finished product particles is good.

The machine adaptability and multi-purpose machine

The product size and shape of the impact crusher are relatively good, which makes it more wide applications. It not only provides finer grade raw materials for ball mills, but also is a frequently selected equipment for artificial sand making.

Wear resistant parts and long service life

We adopt the high strength and wear resistance hammer head, which can save materials and reduce waste. It improves the traditional hammer model, which enhances the service life and safety of the hammer.

Impact Crusher for Sale

If you are interested in our products, please get in touch with us as soon as possible. We will give the reasonable price. As we know, the impact crusher design adopts advanced structure and model. They are very popular in the crushing process. If you have time, welcome to visit our factory in China. We have more useful information and help you. Please directly email us when you have some ideals.