Hollow brick making machine is the new generation equipment which combines the current domestic and international similar features. In addition, according to the market needs, the product development is very popular with many people. Our company ‘s hollow block making machine has compact structure and strong rigidity. What’s more, the equipment adopts the most advanced technology, with large transmission force, and stable operation.

| Brick | Size(L*W*H) | Pcs/Mould | Cycle molding | Pcs/Hr |

| hollow bricks | 390*190*190 | 3 | 15-20s | 540-720 |

| solid blocks | 200*100*60 | 10 | 15-25s | 1500-1800 |

| interlocking bricks | 225*112.5*60 | 8 | 15-25s | 1200-1400 |

| Brick | Size(L*W*H) | Pcs/Mould | Cycle Molding | Pcs/Hr |

| paving blocks | 200*100*60 | 16 | 18-23s | 2504-3200 |

| interlocking bricks | 200*160*60 | 10 | 18-23s | 1565-2000 |

| solid blocks | 240*115*53 | 28 | 15-17s | 5930-6720 |

| hollow bricks | 390*190*190 | 4 | 15-20s | 720-960 |

Hollow Brick Making Machine Design

The machine is very popular from various countries. It has standard brick machine production line. In addition, it has novel design and reliable performance. According to the convenient operation, it is favored by deep users. Our products have exported to more than 100 countries and regions such as USA, India, Pakistan, South Africa, UK, and etc.

| Brick | Size(L*W*H) | Pcs/Mould | Cycle Molding | Pcs/Hr |

| paving blocks | 200*100*60 | 21 | 18-23s | 3287-4200 |

| interlocking bricks | 200*160*60 | 12 | 18-23s | 1878-2400 |

| solid blocks | 240*115*53 | 32 | 15-17s | 6500-7800 |

| hollow bricks | 390*190*190 | 6 | 20-25s | 864-1080 |

Fully Automatic Hollow Brick Making Machine

Fully Automatic Hollow Brick Making Machine Design

Automatic brick machine can different types. The equipment can be designed with different sizes of production and the different degrees of automation. The output of automatic brick machine is generally large. Its products are mostly used in large working sites like high-rise buildings. In addition, the automatic free burning brick machine belongs to the vibration forming of the hydraulic transmission machine. It is higher than the requirements for the strength of load-bearing wall materials. It can realize the automation operation of PLC computer program control.

Various Models of Automatic Hollow Brick Machine

The complete equipment operation can be easily realized by several personnel. It is easy to realize the production of various shapes of bricks such as standard bricks, hollow bricks, perforated bricks, road tiles, road rock bricks, etc. by simply changing the mold.

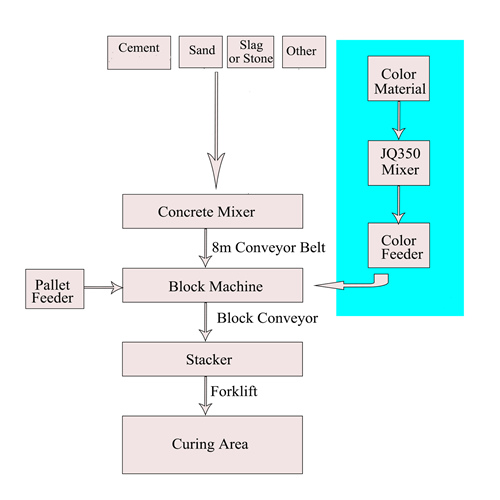

Various System of Hollow Brick Making Machine Production Line

The Fully Automatic Brick-free Vibration System

It adopts the split-type vibration technology is used to expand the effective vibration area, which greatly improves the quality and output of the product, and effectively extends the life of the mold. The vibrating box adopts a hanging structure, which can withstand severe vibration without damage and breakage. The vibrating shaft adopts the eccentric synchronous rotating structure to generate the excitation force in the vertical direction, which can make the fabric and the forming effect good.

Brick Machine Cloth System

The jaws of the skip are combined to make the production site easy to replace. The fabric mechanism adopts a reciprocating push-pull type to make the fabric uniform, which can ensure the consistency of the height and weight of the concrete product. It has high speed.

| Brick | Size(L*W*H) | Pcs/Mould | Cycle Molding | Pcs/Hr |

| paving blocks | 200*100*60 | 28 | 18-23s | 4382-5600 |

| interlocking bricks | 200*160*60 | 20 | 18-23s | 3130-4000 |

| solid blocks | 240*115*53 | 42 | 15-17s | 9000-10000 |

| hollow bricks | 390*190*190 | 8 | 20-25s | 1150-1440 |

Moulding Mechanism of Brick Machine

The mechanism mainly uses two lower mounted cylinders to control the lifting and lowering of the moulding seat under the frame. The top of the rack uses a rocker-type rigid synchronizing mechanism, which can ensure that the mold frame is smoothly lifted. It may not damage the surface of the forming brick.

Fully Automatic Hollow Brick Machine Fabric System

The fabric machine lifting frame is controlled by hydraulic system. The fabric face bucket is connected by rubber spring and lifting frame to provide shock absorption effect. At the same time it can prevent residual material from being shaken. The material door can control the hopper open and close. It can achieve uniform fabric.

| Size(L*W*H) | Pcs/Mould | Pcs/Hr | Pcs/8Hr |

| 400*100*200 | 9 | 1080 | 8640 |

| 400*150*200 | 7 | 840 | 6720 |

| 400*200*200 | 6 | 720 | 5760 |

| 400*250*200 | 4 | 480 | 3840 |

Automatic Hollow Brick Machine Brick Feeding System

This system is equipped with one automatic automatic brick-laying machine. The brick-laying machine uses a belt, which can drive the pallet out of the brick to reduce the wear of the pallet. The brick-laying machine is equipped with a roller brush. The height of the roller brush holder can be adjusted by the screw nut, so that the whole process is more accurate and faster.

The Automatic Hollow Brick Machine Palletizing System

The system adopts an electronic control system and electrical components, which has a rational human-machine interface. The proximity switch and the photoelectric switch are used to control the start and stop time. In addition, it can control the the translation distance and the rotation angle of the cylinder, and the high-sensitivity displacement sensing. It can control the lift and lower height of the code clamp, and has a protection function.

| Size(L*W*H) | Pcs/Mould | Pcs/Hr | Pcs/8Hr |

| 400*100*200 | 16 | 3840 | 30720 |

| 400*150*200 | 12 | 2880 | 23040 |

| 400*200*200 | 10 | 2400 | 19200 |

| 400*250*200 | 6 | 1440 | 11520 |

Fully Automatic Hollow Brick Machine PLC Control System

The whole process of the block forming machine adopts PLC intelligent control. Through the touch screen, it can set the technical parameters such as flow rate and pressure of each action, which can achieve an ideal control condition.

Main Control Units of The Standard System

The control system mainly consists of three control units.

- It has automatic mixing program control system for batching.

- It has automatic control system for forming machine, transporting machine, lifting and unloading machine.

- It has palletizing machine control system.

The electrical components of this system adopts the many imported brand products, which can ensure product’s quality and safety. It will have the reliable performance and low failure rate.

Aimix Group – Hollow Brick Making Machine for Sale In China

Our company is strictly committed to principle with equality and mutual benefit and customers first. We can offer the excellent pre-sales service, sales, and after-sales service.

Pre-sales service

If you have needs, we can offer free guidance with market analysis, investment planning, site design, raw material formula, etc. Our team can provides customers with details about the machine the clients want to buy. We can carefully introduce the product’s function and applications, which makes the customers learn the basic product performance.

Sales

We have the ability and meet the customers’ requirements about various types and sizes. We timely transmit customer information to ensure that customer requirements are accurate and fully realized. We can guarantee to deliver on time according to the contract. We can ask about the acceptance of the goods, including whether the product quality can meet the customer’s needs, transportation methods, packaging conditions and other customer requirements.

After-sales service

When the user requests on-site installation service, the company will send professional technical service personnel to participate in the unpacking acceptance. We can guide the installation and commissioning work until the equipment is in normal operation. In addition, we can provide corresponding technical training services free of charge.

If you are interested in hollow brick making machine, please get in touch with us as soon as possible.