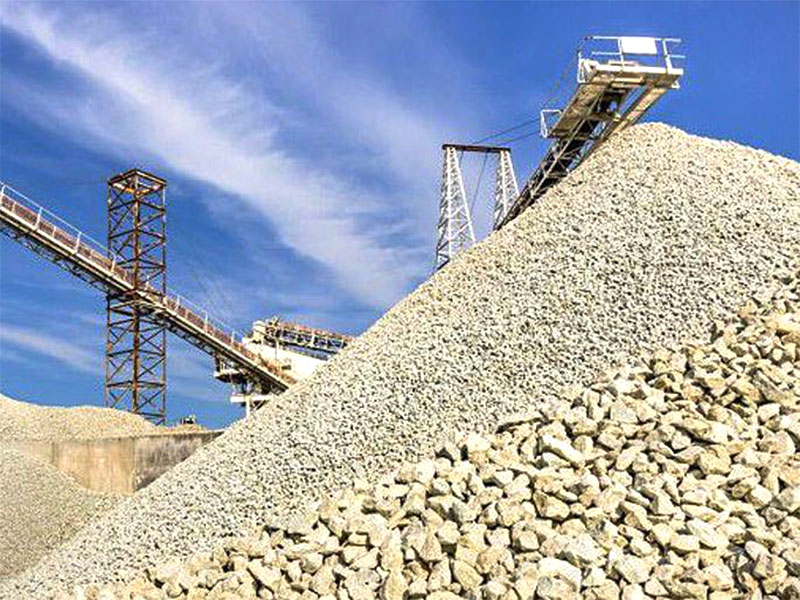

Sand and gravel aggregate refers to a type of mineral material used in construction and foundation engineering projects, mainly including sand and gravel. In the construction industry, sand and gravel aggregate is an important component of concrete, asphalt and other building materials, and is widely used in various fields such as roadbed, railways, tunnels, and house construction.

One of our clients is a local concrete and asphalt supplier. Some time ago, he purchased a concrete batching plant and an asphalt mixing plant to facilitate the production and sale of finished concrete and asphalt. He urgently needs a large amount of sand and gravel aggregates in order to normally operate these two sets of plants. Therefore, for the sake of producing enough sand and gravel aggregate, he needs a set of crushing equipment to help him complete the crushing and processing of raw stones.

Thus, he found us and wanted us to recommend him with a suitable crushing equipment model. After we received his inquiry, we immediately contacted him and learned more about his current situation and needs.

Customer Status & Needs

The customer has just obtained the qualification to mine a mountain, and the stone material of this mountain is granite. When it comes to granite, its excellent hardness and durability make it an ideal material for construction. The customer wanted us to help him design a granite crushing plan.

- Production Requirements: Daily working hours are 8 hours, and daily production requirements are 1440-1600TPH

- Granite Size: ≤500mm

- Required Sand and Gravel Aggregate Size: 0-5mm, 5-10mm, 10-20mm, 20-31.5m

- Budget Range: Within USD 200,000

- Special Requirements: The stone particle size must be good.

- Whether A Mobile Station Is Required: No

After getting the customer’s requirements, our engineers immediately start analyzing the customer’s requirements.

Preliminary Ideas

Our initial idea is this:

- The customer has no preference for mobile crusher plants, therefore, we chose to design a stationary crushing plant for the customer.

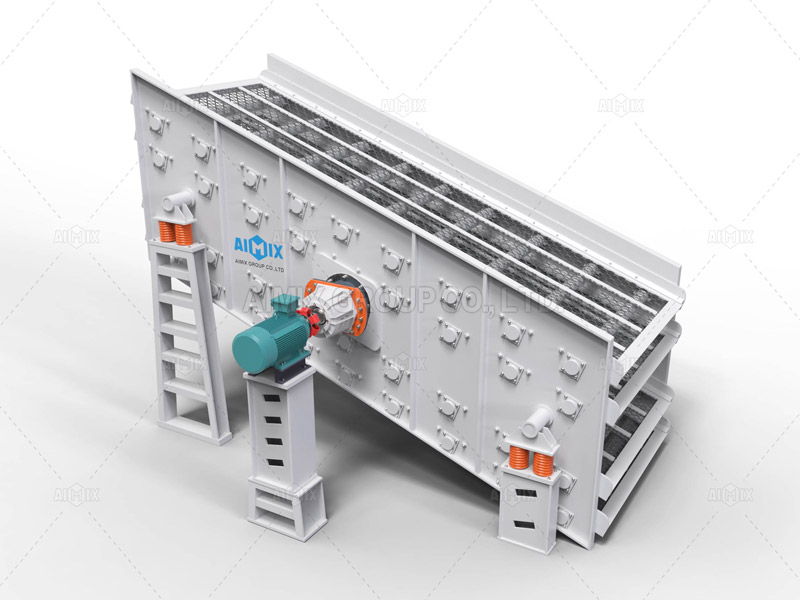

- Since customers have multiple size requirements for the final particle size of the product, which contains fine sand, so this requirement must be met with two-stage crushing. In addition, the customer also said that the discharge particle size of the stones must be good. Therefore, the selection of the secondary crusher in the two-stage crushing is very critical. It must not only meet the customer’s requirements for the discharge ratio of fine materials, but also satisfy the good particle shape of the discharged material.

- The customer’s daily production demand is 1440-1600TPH, namely hourly production demand is 180-200TPH.

After confirming the above information, we initially developed a set of 200TPH stationary crushing plant. Its configuration and price are as follows:

Final Configuration

- Two-stage Crushing: the primary crushing uses a jaw crusher, and the secondary crushing uses an impact crusher. In order to meet the customer’s production requirements, we selected APJ-7510E (jaw crusher), and APC-1315X impact crusher for their configurations.

- Final Price: Including the feeder, vibrating screen, and belt conveyors, the price of the entire crushing equipment is USD 180,000, which well within the client’s budget.

When we submitted the plan to the customer, our customer was very satisfied and especially praised the 3D drawings we provided.

Next, we communicated with the customer and determined the installation and delivery of the equipment. Since the customer urgently needed this equipment, he quickly placed an order. The whole purchasing process was very smooth. Now, this crushing equipment has been successfully installed and put into operation. The customer was at his site and sent us some on-site working videos of the equipment, now we share them with everyone.

Thanks for your reading.