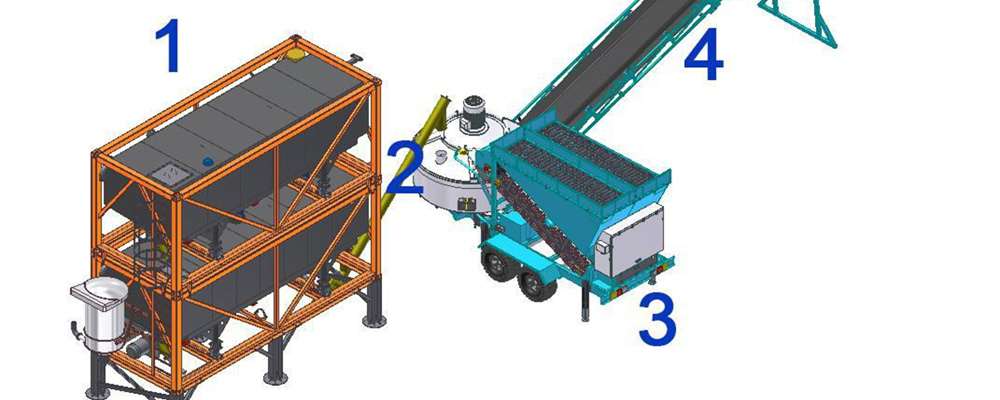

Cement silo is generally used in the bulk cement storage of the concrete batching plant, which is a closed tank material for storing bulk materials. In addition, it is suitable for storing various dry small particles, materials or powers such as grain, cement, fly ash, and other bulk materials. They can be used in conjunction with a screw conveyor to transport materials to various locations.

Hot Cement Silo Types for Sale

Cement Silo for Sale

The silo is common use in concrete batching plant. In general, the we have a series of the concrete mixing equipment. They have the matched silos for needs. Of course, if the users want to purchase a silo or choose the other types, our company can customize the products you want to get.

50 ton cement silo

50 ton Cement silo is one of the most important components of various rural mixing plant. It consists of the tank steel structure, outriggers, ladders, guardrails, dust removal equipment, level gauges, etc. The appearance of the cement silo is cylindrical and the bottom consists of four bars. The round pipe legs support all the silos. The whole silo is constructed of steel.

When you choose 50 ton silo, we can offer the reasonable advice. In addition, it depends on the operation condition and environment. Hope to get right one.

Cement Silo Capacity

In general, 50 ton and 100 ton cement silos are available below 50 stations. In addition, there are 100 ton, 200 ton, 300 ton, 400 ton, 500 ton and others. Owing to the large flexibility of cement silos, the customers can choose suitable products to match according to the needs. For 50 ton or below, it is generally made into a whole welded type. For 50 ton, 100 ton, 150 ton, 200 ton or more, it is generally made the body with bolted type. Of course, the transportation method of the split and the whole is different. Of course, we can meet the customers’ requirements about different tons, such as 40 ton, 50 ton, 60 ton, 70 ton, 80 ton, 90 ton, 100 ton, 500 ton, etc.

Cement Silo Types – Catalogue of All Types of Silo

There are four main types including with horizontal silo, bag type silo, transportation of silo, and bolted type silo.

Horizontal cement silo

Horizontal cement silo has various types with frame type, container type, and stackable type, and wheel type. Frame type adopts the container transportation. Container type adopts the framework transportation. Stackable type adopts the framework transportation. In addition, the wheel type adopts the container transportation. Of course, we can accept the customized products for these different types of silo.

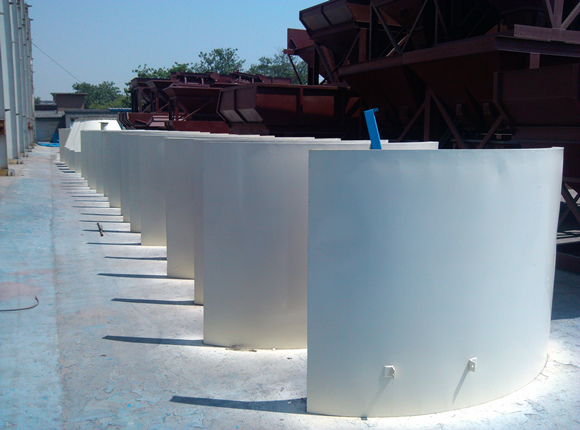

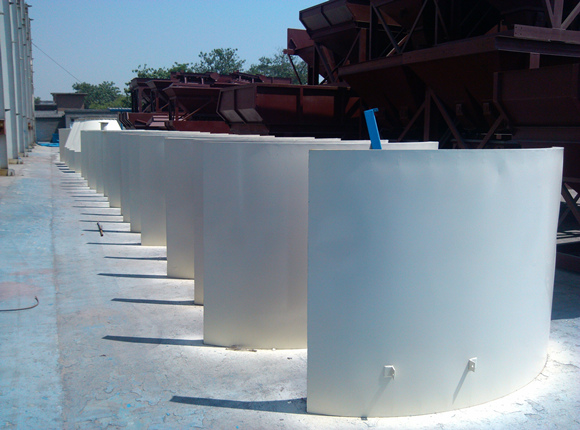

Bag type silo

Bag type silo adopts the container transportation. In addition, the silo has different tons to meet customers’ requirements. It has the advantage without installation need. In conclusion, it has simple operation and easy maintenance.

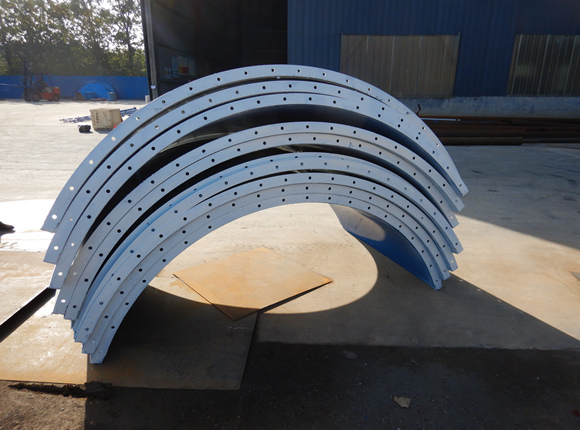

Bolted Type Silo

It has different capacities according to different requirements with 30t, 50t, 100t, 150t, 200t, 300t, 500t, 800t, 1000t and others. We can accept the customization for your concrete mixing equipment. The silo is combined by four main parts with the cover, wall sections, cones and supporting legs. All parts are pressed by special machine and mould, especially the wall sections which can be changed every place on the wall. The silo can be dismantled into many parts when transport, and can be installed with bolts easily, so it is easy to transport in container.

Transportation of silo

If the customers have the special needs, you can get in touch with us as soon as possible. We have the professional team to help the customers get the reasonable transportation and installation. If you have some other ideals, please give the reasonable advice. Please directly email us.

Cement Silo Components

Cement silos are mainly composed of the several parts including the dust-catcher, guardrail, ladder, body of bin, level indicator, feeding tube, pressure safety valve, manual butterfly valve, and holder.

Dust-catcher

When the bulk cement pump truck transports the power into the silo. A pressure difference will be formed inside and outside the cement silos. The gas will be discharged from the inside of the silo. It is easy to generate dust and pollute the air. The function of the dust collector can filter the gas discharged from the chamber. At the same time, the pressure inside and outside the chamber reaches a balance. Some dust collectors are equipped with a vibration device, which will shake off the collected dust at regular intervals.

>The Guardrail

The guardrail is mainly for protection. When the cement silo needs to be overhauled, the users need to climb from the outer ladder to the top and enter the interior of the cement silo from the top access. Overhaul and cleaning of the dust collector also need to be done at the top.

The Level Gauge

The level gauge is used to measure the height of the power in the cement silo. It has a wide variety. Our factory mainly use a blade level gauge. The basic principle that controls the signal light to achieve the warning function according to whether there is material in the contact range of the level gauge. One or two can be installed in a cement silo product.

The feeding Pipe

A bulk cement pump truck is connected to the lower end of the feeding pipe. The upper end is directly connected to the top of the cement silos. Generally, the integral part of the cement silo and bin is hidden inside the bin.

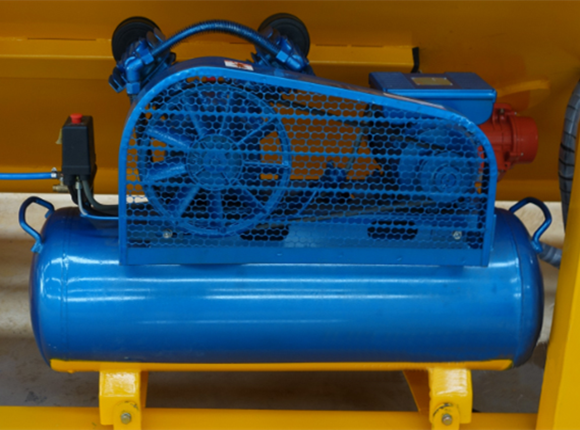

Pressure Safety Valve

Generally, owing to the silo body is large, the outlet is small. When the cement silos are discharged, the materials can’t be smoothly outputted. The breaking of arch can deal with the problem. When the cement silos are discharged, the compressed air is connected to the broken arch. The air gun is placed in the warehouse so that the material is loose and the discharging is comfortable. In addition, 50 ton cement silo is equipped with 3 broken arches. It is suitable with 6 broken arches for 50 ton or more. The users can choose automatic or manual control. It depends on how the system is controlled.

Manual Butterfly Valve

The manual butterfly valve is the connection part between the cement silo and the screw conveyor. In normal operation, the manual butterfly valve is opened. The power enters the spiral conveying pipe from the cement silos. When the screw conveyors need to be inspected, the manual butterfly valve needs to be closed.

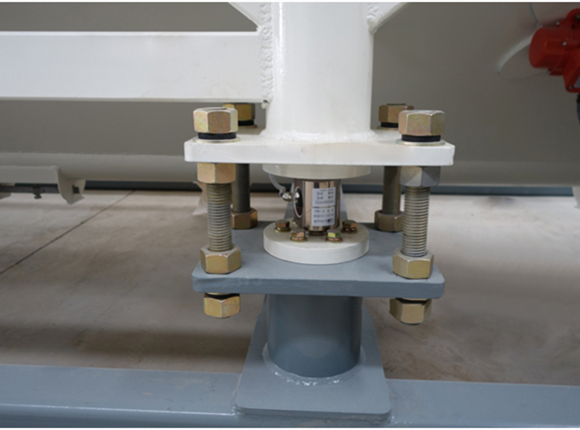

Holder

The bracket is located at the bottom of the cement silo and is the part connected to the ground to support.The height of the bracket is variable and can be changed according to different requirements. The bottom of the bracket is connected to the foundation.

Cement silo is generally used in the bulk cement storage of the concrete batching plant, which is a closed tank material for storing bulk materials. In addition, it is suitable for storing various dry small particles, materials or powers such as grain, cement, fly ash, and other bulk materials. They can be used in conjunction with a screw conveyor to transport materials to various locations.

2000 Ton Cement Silo Installation Transportation

Various Advantages Of Cement Silo

- It has reliable performance and competitive price.

- It has long service life

- It has professional designer and manufacturer

- All material of silo we use special steel structure such as ladders, guardrail or support leg, silo body. This kind of steel has great performance in strength, plasticity and welding.

- We have 30 years experience in producing cement silo.

- All of our cement silo are designed under strict mechanics principle, Keep loading capacity and ensuring safety.

Cement Silo Cases

Of course, our products have exported to over 100 countries and regions. In addition, we have professional team to help the users installation. There are some cases which can help the customers to learn more useful information. It has been installed in Russia, Philippines, Thailand, Republic of Botswana, Indonesia, China mainland and others. If you are interested in our products, please get in touch with us as soon as possible.